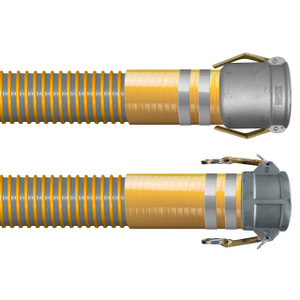

Kuriyama Tigervapor TV for tank truck vapor recovery. Constructed with non-permeable polyurethane (TPU) tubes. They have been proven to remain crack and leak resistant under the harshest of conditions. They easily handle gasoline/fuel blends made with various additives including methanol, ethanol, toluene, naphthas, kerosene, benzene, MEK and MTBE's without degradation (aromatic content not to exceed 50%). And they remain super flexible, even in sub-zero weather.

Notes: Price is per foot. Max length 100 ft. rolls. Hose only - no ends. Cutting the hose, exposing the wire, and attachment of sleeve (if sleeves are ordered separately) is all included in our price. Want to add a banding sleeve for the end of your hose? Please search on these part numbers: 2 in. Sleeve (KUSLVVAP2X3), 3 in. Sleeve (KUSLVVAP3X3), and 4 in. Sleeve (KUSLVVAP4X3).

Features

- Lightweight: Much lighter than conventional TPR/rubber hoses

- Superior Flexibility: Especially in sub-zero weather

- "See-Through" Construction: For visual confirmation if fuel backs up into the vapor recovery system

- Grounding Wire: Durable multi-strand copper wire dissipates static electricity - Physically extract wire from the rigid helix and bond to the metal coupling (or by other means) to ground

- Easy Slide Helix: Rigid counter clockwise helix design protects hose tube from cover wear; allows hose to slide easily over rough surfaces

- Biofuel Compatible: Revolutionary polyurethane compound - Specially designed to handle gasoline, ethanol, diesel and biodiesel vapors

- Non-Permeable Polyurethane Construction: Won’t swell or become stiff like conventional TPR/rubber hoses - Long life reduces operating costs

- Phthalate Free

- Made in the USA

Specifications

- Series: Tigervapor TV

- Size: 2, 3, & 4 in.

- Length: Per ft.

- Hose Ends: None - Hose Only

- Construction: Polyurethane (TPU) Tube with Rigid PVC Helix and Embedded Grounding Wire

- Service Temperature Range: -40°F to +140°F (-40°C to +60°C)

- Biofuel Compatible: Specially Designed to Handle Gasoline, Ethanol, Diesel and Biodiesel Vapors

| Size | I.D. | O.D. | Working Pressure | Working Pressure | Minimum Bend Radius (@68°F) | Weight | ||

|---|---|---|---|---|---|---|---|---|

| @68°F | @104°F | @68°F | @104°F | |||||

| 2 in. | 2.02 in. (51.3 mm.) | 2.46 in. (62.5 mm.) | 17 PSI | 6 PSI | 21 in. Hg | 12 in. Hg | 3.0 in. | 0.51 lbs./ft. |

| 3 in. | 3.03 in. (77.0 mm.) | 3.57 in. (90.7 mm.) | 11 PSI | 5 PSI | 18 in. Hg | 10 in. Hg | 3.5 in. | 0.78 lbs./ft. |

| 4 in. | 4.04 in. (102.6 mm.) | (4.61 in. (117.1 mm.) | 9 PSI | 4 PSI | 13in. Hg | 8 in. Hg | 4.5 in. | 1.10 lbs./ft. |