Lechler tank and equipment cleaning nozzles are used for thorough cleaning of all kinds of tank sizes, machines and equipment. Cleaning nozzles achieve high cleaning performance even at low pressures. This saves on high energy costs. The nozzles are driven and lubricated by the cleaning fluid and are therefore maintenance-free and reliable.

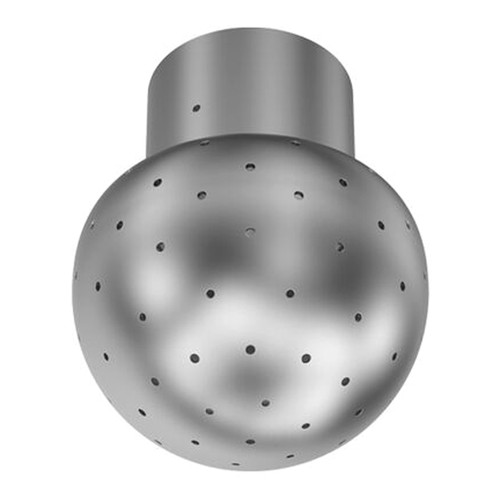

Stationary spray balls do not rotate and therefore require considerably more fluid. They are used primarily for rinsing tanks. The force of impact when using a liquid jet on a surface plays an important role in cleaning technology. The impact surface is the area where the droplet strikes. The smaller the surface area, the greater the impact values. Increasing the flow rate by using a larger nozzle increases the impact, assuming that the other parameters (spray angle, pressure and medium) remain the same.

Features

- No moving parts

- Self-draining

- Proven use in many applications

- Robust compact design

- Threaded connection

- Suitable for very high temperatures

- Suitable for operation with steam air

Specifications

- Stationary spray ball

- Spray angle: 360-degree

- Connection: 2.08 in. Slip-on

- Secures with #5 clasp pin (included)

- Recommended operating pressure: 30 PSI

- Flow rate: 180 GPM (670 LPM)

- Max tank diameter: 18 ft.

- Maximum operating temperature: 392° F

- Maximum ambient temperature: 482° F

- Surface quality: ≤ 8 Micron

- Material: Stainless steel

- Insertion diameter: 0.79 in.

- Narrowest free cross section: 0.13 in.

- Installation: Operation in every installation position

- Suitable for steam

- No Bearing

- Recommended filter: Smaller than the narrowest cross-section

- Meets FDA requirements