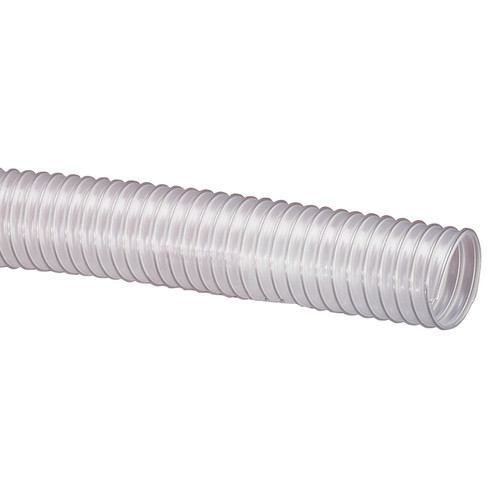

The Norres AIRDUC® PUR 355 AS is a flexible hose designed for industrial applications involving dust, fumes, and light materials. It's built for durability with good abrasion resistance and can handle various chemicals and low temperatures.

This hose is commonly used in manufacturing and industrial settings for tasks like dust extraction, ventilation, and material transfer. Its antistatic properties and flame retardant build make it suitable for use in areas with explosion hazards.

Features

- Highly abrasion resistant

- Medium-heavy duty

- Microbe resistant

- Good resistance to oil, gasoline and chemicals

- Very good low temperature flexibility

- Flame-retardant according to: UL94-V2 & DIN 4102-B1

- Permanently antistatic wall: according to ISO 8031 electrical and surface resistance <10⁹ Ω (according to TRGS 727 <2,5*10⁸ Ω*m and NFPA 652 10⁸-10⁹ Ω)

- in accordance with ATEX 2014/34/EU (1999/92/EC) and German TRGS 727: pneumatic transport of flammable dusts and bulk materials (Zone 20, 21, 22 inside), aspiration of combustible dusts (Zone 22 inside),

- in accordance with ATEX 2014/34/EU (1999/92/EC) and German TRGS 727: for conveying for flammable liquids (inside zone 0, 1, 2), for conveying for non-flammable liquids, for use in zone 1 and 2 (gases), for use in zone 0 (gases)

- conforms to the safety regulations of the German Wood Trade Association

- according to DIN 26057 Type 2

- Conforms to RoHS guideline

Specifications

- Hose O.D.: 4.21 in.

- Pressure: 9.20 PSI

- Vacuum: 3.99 inHG

- Bending Radius: 2.68 in.

- Weight (lbs./ft.): 0.540 lbs./ft.

- Temperature range: -40°F to 195°F (255°F for short periods)

- Material/Design:

- Spring steel wire firmly embedded in the wall

- Wall: permanently antistatic premium ester-polyurethane (Pre-PUR)

- Wall thickness 0.03 in. approximate

Applications

- Flexible hose/ ducting for abrasive powder, bulk material, granulate and for gases

- Printed circuit board drilling machine (PCB)

- Offset printing machine: air supply, air supply cabinet

- Air supply: UV dryer, IR dryer

- Extraction unit, dedusting system, filter system, oil mist extraction

- Chemical industry: chemical vapours, vapour return hose at loading arm, paint steam, spray mist extraction

- Explosion hazard area

- Textile industry, fiber extraction: spinning machine, knitting machine, weaving loom machine

- Animal stall, animal shed: barn ventilation

- Clean room ventilation, semiconductor production machine

- Compressor, side channel blower, vacuum pump, pressure pump, pump

- Surface preparation: shot blasting/ sand blasting recovery e.g. at blasting chamber, ship yard, stripping machine, flooring preparation machine, grinding machine

- Municipal vehicle: sweeper, sweeping machine

- Municipal vehicle: lawn mower, slope mower, leaf blower/ leaf collector

- Scrubber, floor cleaning machine

- Heating hose: exterior hose as protection hose

Downloads

Installation Instructions (PDF Download)

Cutting and Assembly Instructions (PDF Download)

ATEX Test Result Report (PDF Download)

UL Test Result Report (PDF Download)