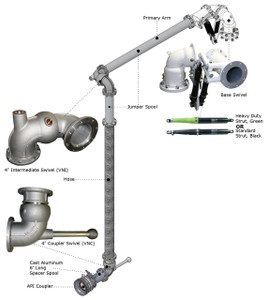

OPW LBM800 Liquip Balance Mechanism Upfeed Right Hand with Green Struts Installed

A benchmark has been set for all bottom loading arms with the introduction of the LBM800. This state-of-the-art design is essential when you require safety and long service life with minimal maintenance. The LBM800 provides effortless bottom loading in petrochemical distribution terminals through the use of the unique design known as the Velvet Touch.

The ability of 360° rotation in the horizontal plane allows the LBM800 to easily move from a parked to loading position, and to service vehicles on either side of the loading bay. While the vertical plane swivel allows users to position the coupler at different heights within the API envelope.

Features

- Superior safety through Liquip's unique gas strut design

- Exceptional durability and minimal servicing requirements thanks to the best in class base swivel assembly and overall design

- Any unit can be easily configured for left hand, right hand, upward and downward configurations on site

- Slimline drop leg bracket provides easy installation and compact overall size

- Enhanced strength and ease of adjustment through a heavy duty adjustment mechanism

- Downtime during installation is reduced by an all-flanged design.

- Outlet spool provides an industry standard 100mm (4 in.) TTMA connection for simple installation

- Adjustable up/down stop that can be set with minimal effort

- Velvet touch provides smooth operation over the entire stroke of the loading arm

Specifications

- Working Pressure: 145 PSI (1,000 kPa)

- Test Pressure: 217 PSI (1,500 kPa)

- Material: Investment cast 4130 steel construction

- Seals: Viton GFLT product seals, HAN dust seal

- Mounting:

- Base flange is 4 in. ANSI 150 raised face flange

- Outlet flange is 4 in. (100mm) TTMA pattern

- Weight: 133 lbs (60.4 kg)

- Operating Temperature: -40° F to 200° F (-40° C to 90° C)

- Min Moment: 650 ft. lbs (90 kg m)

- Max Moment: 1,800 ft. lbs (250 kg m)

- Brass Retainer Plug Thread: 1/4 in. UNF

- Up/Down Angular Movement: -15° to 15° (from horizontal)

- Typical Horizontal Spacing: 24 in. (650 mm)

- Typical Vertical Spacing: 18 in. (450 mm)

- Typical Radius of Arm: 50 in. to 80 in. (1300 mm to 2000 mm)

- Typical Number of Arms per Bay: 6