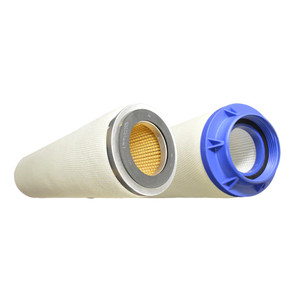

Velcon’s DI coalescers in combination with DSO separators, contaminated fuels are cleaned to a level that meets stringent downstream fuel cleanliness standards for petroleum based diesel fuels.

The first stage in the DI coalescer removes particles through an inside-out flow and coalesces emulsified water into large droplets, which then fall to the housing sump.

In the second stage, an outside-in process, the DSO separator creates a hydrophobic barrier to block the coalesced water droplets from flowing downstream of the housing.

This multi-stage design assures the fuel is conditioned to a clean and dry state, ready for use.

Tiered Ratings

- Velcon’s 4 micron coalescer combines leading-edge particle removal with world-class coalescing technology to provide optimal fuel cleanliness

- The 10 and 25 micron rated filter coalescer provides effective particle removal with industry proven coalescing technology

Surfactants

- Water coalescing is not effective in the presence of fuels containing high levels of surfactants/alcohols or unrefined biofuels

- Detergents and additives inhibits the ability of coalescers to effectively remove water by reducing Interfacial Tension (IFT) and can eventually disarm coalescers

Specifications

- All filter components compatible with petroleum based diesel fuels

- Downstream free-water level typically below 50ppm

- Recommended change out pressure: 25 psid (1.7 bar)

- Nitrile Rubber sealing materials standard

- Maximum operating temperature: 150°F (65°C)

- 6” (15.2 cm) outer diameter

- DI - coalescer flow direction - inside to outside

- DSO - separator flow direction - outside to inside