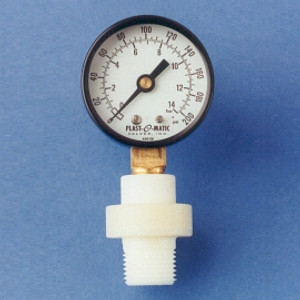

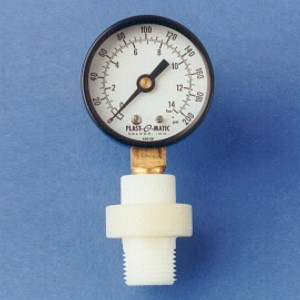

Each GGME Gauge Guard features a durable and flexible diaphragm which serves as a protective barrier between the process fluid and instrument. The internal space on the instrument side of the diaphragm must be solidly filled with a suitable liquid in order to accurately transmit the process pressure to the instrument. Diaphragm Seals are designed for a maximum working pressure of 200 PSI (13.8 bars). Additionally, design of the diaphragm and housing will prevent rupture of the diaphragm in the event of accidental removal of the gauge.

Material: Polypropylene

Features

- Diaphragm Seal, instrument isolator, Gauge Guard...no matter what you prefer to call it, this device provides an excellent and important protective barrier between process fluid and the pressure/vacuum gauge or instrument.

- Increase product reliability and reduce system downtime caused by failure of instruments not protected by seals.

- Exceptionally low unit cost - now makes it feasible to protect even moderate priced instruments.

- Compact size makes these isolators ideal for limited-space installations.

- Liquid pressures to 200 PSI with ±4% accuracy. Choice of Nitrile Rubber or FKM (Viton) seal will handle most applications.

- Use with gauges, transducers, and pressure switches.

- Simple to fill and install.

- Hermetically-sealed uni-body construction - molded body avoids possibility of dangerous leaks.

- For use with highly aggressive or ultra-pure liquids.

- Diaphragm safety - If the gauge or instrument fractures or is removed from the guard while the system is pressurized, the diaphragm will automatically seal against leakage to the atmosphere.

- Polypropylene bodies for excellent chemical compatibility and temperatures to 185° F (85° C). The upper half (instrument side) is glass-filled polypropylene; the lower half (process side) is 100% natural, unpigmented virgin polypropylene.

for orders over

for orders over