Capture hazardous spills from railroad tanker cars. Ultra-Track Pans have been designed to provide railroad spill containment at industrial rail sidings and locomotive maintenance facilities. The modular design can be used for spill control for everything from small drips during maintenance to catastrophic spills from tanker cars. Available in virtually any length, Ultra-Track Pans may be used to collect small spills and leaks OR to capture and channel off significant spills caused by defective equipment or a major overflow. Prevent costly cleanup and regulatory fines from railcar spills and chemical spills. Modular Track Pan design can be customized to meet your specific railroad spill containment needs. Long work life - Estimated to perform 20-30 years.

Note: Approval needed see the Rail Height Approval Sheet attached to confirm all is needed based on area covered & system looking to be put in place. Lead-times can vary. Call a JME Sales specialist 800-333-3331 to get the detailsFeatures

- Modular design - Center and Side Pans are 53.5" long; railroad spill containment areas can be easily assembled to any length desired

- All-polyethylene construction - Rugged Track Pans withstand harsh chemicals and are designed to function in temperatures ranging from -40°F to +140°F

- UV inhibitor in polyethylene resin resists degrading effects of sunlight, adding years to outdoor service life.

- Sealed System - Polyethylene gaskets keep spills from falling between the rails and Pans.

- Trucks and other vehicles can drive over Track Pans with grates in place (NOTE: To drive over Track Pans, firm footing must be beneath the Pans; also must "ramp up" to Side Pans with asphalt or concrete)

- Below grade piping - All Center and Side Track Pans are molded with pipe fitting locators at their lowest point. Below grade piping can be installed to channel large spills to oil/water separators, holding ponds, etc.

- Unique storm water feature is designed to eliminate "pooling" of rain that falls on top of the Center Pan Covers; rain is channeled onto the ballast between the tracks, stays out of the Pans.

- Low Maintenance - unlike carbon steel track pans, Ultra-Track Pans will not rust or corrode. Polyethylene resin is treated with a UV inhibitor, resists degrading effects of the sun.

- Low Cost Installation- Lightweight Track Pans can be easily installed without heavy lifting equipment, i.e., forklifts, cranes, backhoes, etc. Minimal tools and labor required.

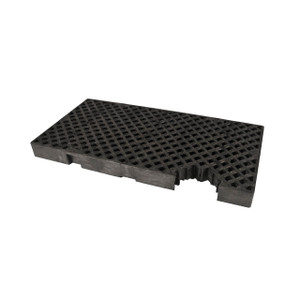

- Slip Resistant Surfaces - Pans, grates and covers have been designed with safety in mind. All top surfaces resist slips when wet or oily.

- Optional Track Pan Covers keep rainwater out of the Pans, providing effective storm water management.

- Polyethylene Covers are left in place until the railcar(s) arrive to be off-loaded or loaded. Lightweight covers mechanically lock into the polyethylene decking and will not blow off in windy conditions.

- Protected by the industry's strongest warranty - Five (5) years against any material or workmanship defects.

Specifications

- Center track pan w/ grates

- 54-1/4 in. L x 55-3/4 in. W x 6 in. H

- 18 Gallon containment capacity

- Includes 2 bulkhead fittings, 4 gaskets and 2 grates

- Meets SPCC and EPA regulations

- Made in the USA

Downloads

Brochure (PDF Download)

Specifications (PDF Download)

Instructions (PDF Download)

Chemical Compatibility (PDF Download)

Adhesive SDS (PDF Download)

SDS (PDF Download)

Rail Height Approval Sheet (PDF Download)